Why scissor switches?

And why you don't see many scissor switch based ergonomic keyboards today

The most satisfying ergonomic keyboard is ultra-low profile. It uses only as much material as needed to function. This isn’t just more aesthetic, it’s also more comfortable. Keys that don’t need to be pushed down far are less tiring, which makes them more ergonomic.

For ultra-low profile designs, switches are the most important decision. They determine most of the keyboard’s height.

When I started this project (rationale here), I first considered using mechanical switches. They’re often the premium option because of their reliability and feel. However, mechanical switches have a few problems:

They’re loud – Some people like that, but to me it’s more of a nuisance. They bother people nearby and on Zoom calls.

Most aren’t low profile – I found one reliable ultra low profile switch (”Cherry MX ULP“), but it was hard to source.

Limited sizes – Mechanical switches only come in set sizes. We needed custom-sized arrow keys to match a 75% laptop keyboard layout.

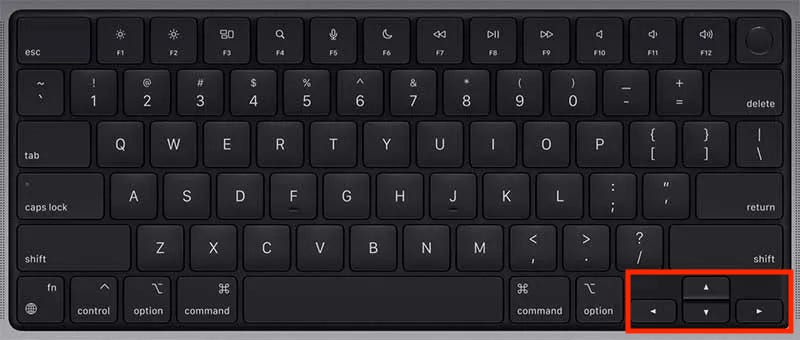

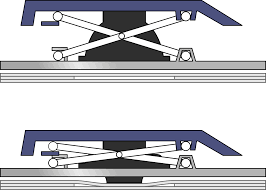

Instead of mechanical switches, we decided to use scissor switches. These are what you see in pretty much every laptop keyboard these days. They are quiet, ultra low profile (~1mm), and can fit our custom key shape requirements.

The issue with scissor switch keyboards though is that you can’t produce them easily unless you go to a manufacturer. It has to do with the way they are put together. Some examples of what makes it hard:

The switches and keys are too thin to 3d print reliably, so you need molds to produce them

The switches fit into tiny hooks in the frame that machines assemble best

Making a flexible PCB and getting the rubber domes for the keys would be hacky to do yourself

Hobbyists can’t solve these problems on their own. Manufacturers, on the other hand, have the machines and the expertise to churn out scissor switch keyboard modules easily.

Because we need manufacturing help to produce this keyboard, I flew to China with a few weeks notice to find manufacturing partners (which is a story for a future post).

Why doesn’t this exist yet?

I think there are a few reasons:

Ergonomic split keyboards are niche - For me, the minimum I need to prevent pain is a split keyboard with tenting (or upward tilt from the inside). These exist but are not that common in the broader market.

People want mechanical switches - Keyboard enthusiasts tend to want mechanical switches. There’s a whole ecosystem that cares about if a keyboard sounds “thocky”, “creamy” or “clicky.” I don’t care about any of that.

Manufacturing hurtles - People who would love an ultra-low profile keyboard don’t want it enough to fly to China and figure out how to build one.

I’m a relatively uncommon user who wants these scissor switches badly enough to try and mass produce a keyboard.

My hope here is that there are enough of us that want this to fund our first mass production run. Consider subscribing to this newsletter to follow along as we build it.

Thanks for reading,

Ryan Peterman

I like the feeling of scissor switches on my MacBook keyboard and I think it would be a great choice for an ergonomic keyboard regarding feel and sound, but a quick thought.

How much harder is it to fix/change scissor keys compared to hot swappable keyboards that allow you to switch the keycaps and switches if something becomes defected? Ergonomic keyboards like the Naya ergonomic keyboard have a modular low profile keyboard that can do this (plus they claim to have “silent”

switches).